ST-12/14 Straightening Machine with Cutting series

零售价

市场价

Product number:ST-12/14

重量

kg

库存

隐藏域元素占位

- Product Description

-

Model ST-12 ST-14 Straightening and cutting capacity (mm) Deformed Steel Bars Φ4-Φ10 Φ4-Φ12 Round Steel Φ4-Φ12 Φ4- Φ14 Straightening Speed(m/min) 30-50 30-60 Power 9kW/380V 11kW/380V Sheared Length(m) 0.30-99 0.30-99 Shearing Error(mm) ±5 ±5 Boundary Size(mm) Machine 1700×720×1000 1840×720×1050 Electric Box 350×230×820 450×290×700 Weight(kg) Machine 355 440 Electric Box 14 12.3

model

ST-12

ST-14

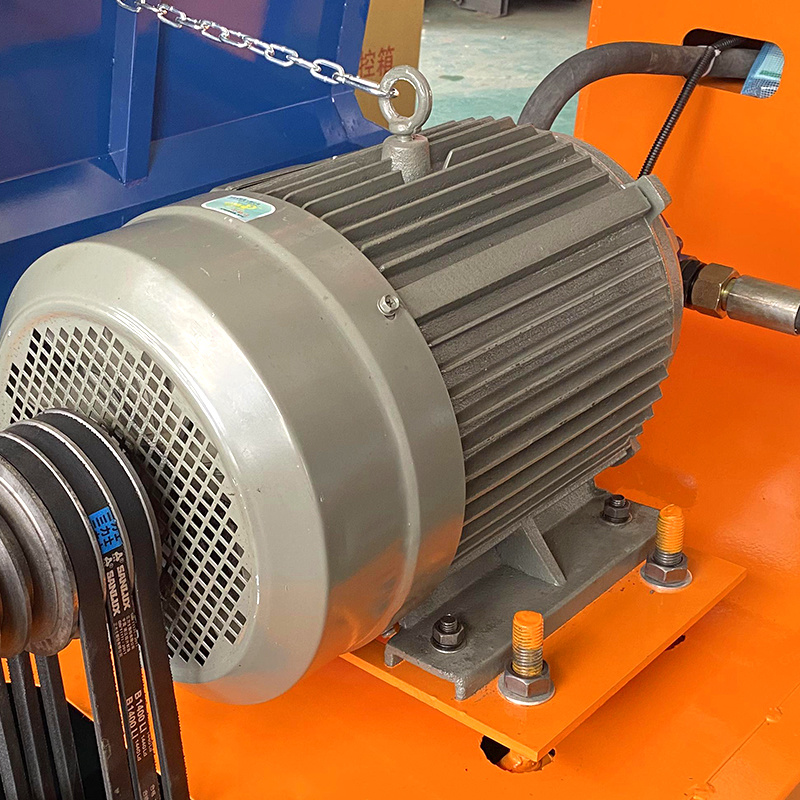

Engine

National standard 9kW

National standard 11kW

Electric appliance

DELIXI

DELIXI

Rack

Thickened material

Thickened material

Bearing

CUBearing

CUBearing

Oil cylinder

Sanrui 63mm cylinder

Sanrui 80mm cylinder

Oil tube

3 layers thickened

3 layers thickened

Horizontal straightening wheel

55×62mm, Cr 12 Mo vanadium, vacuum quenched

70×70mm, Cr 12 quenched

Straightening frame

Gezheng 700mm straightening frame, 22mm thickened

Juncheng 800mm straightening frame, 22mm thickened

Boundary dimension

1700×720×1000mm

1840×720×1050mm

Total weight

355kg

440kg

Electric box dimension

350×230×820mm

450×290×700mm

Electric box weight

14kg

12.3kg

Speed

Double speed

Double speed

Cutting tolorance

±5mm

±5mm

Max straightening speed

~50m/min

~60m/min

Min cutting length

30cm( Low speed)

30cm( Low speed)

Hydraulic hoop bending machine

HIGH SPEED FREQUENCY CONVERSION

ADJUSTABLE TO 80 METERS PER MINUTE

Efficient and stable

Sturdy and durable

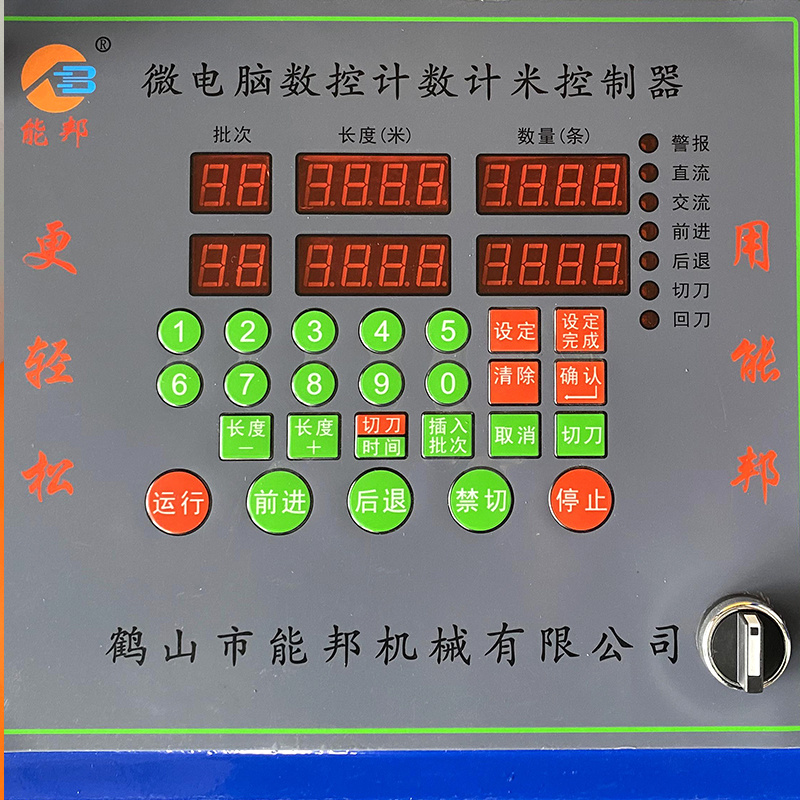

1. The straightening machine series all use CNC intelligent control, the straightening and cutting of the rebar, once can be formed, simple operation, accurate measurement, can meet the straightening needs of various rebar.

2. National standard of pure copper motor, more powerful. Specially designed high-strength straightening frame, straightening wheel, thickened shear cylinder and cut, as well as three-layer thickened tubing, are twice as wear-resistant and durable as similar workpieces. The machine has better performance, more stable and longer life. Upgraded solenoid valve and thickened traction box plate make aligning efficiency and effect greatly improved.

Service Guarantee

DIRECTLY SALES

FROM FACTORY

LIFE LONG

SERVICE

SOLUTION

WITHIN I HOUR

7*24 HOURS OF

TECHNICA

EXPERIENCE

SUPPORT FOR

ANYWHERE

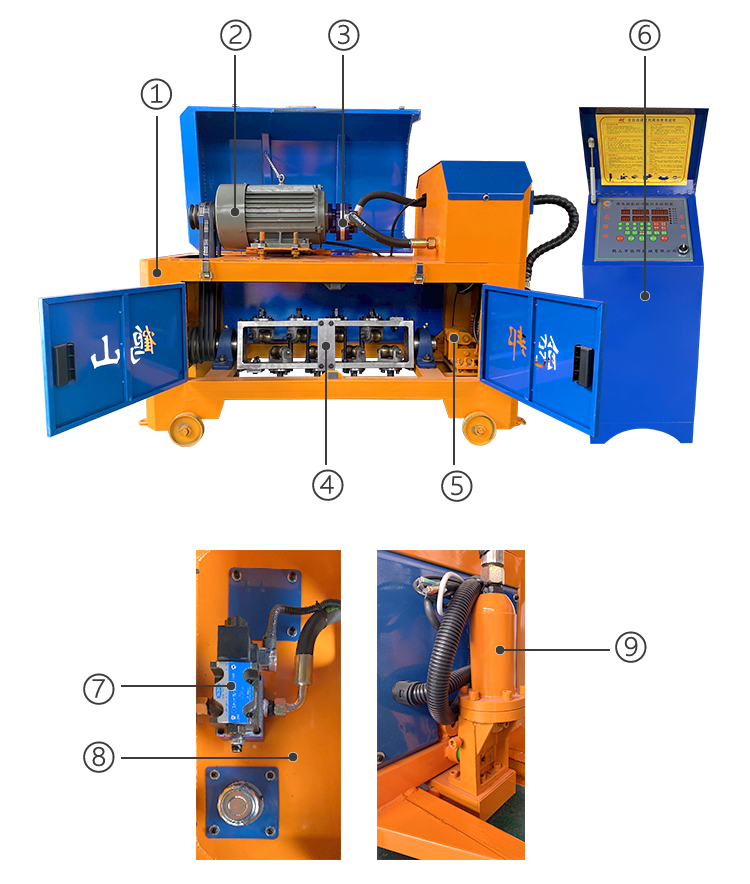

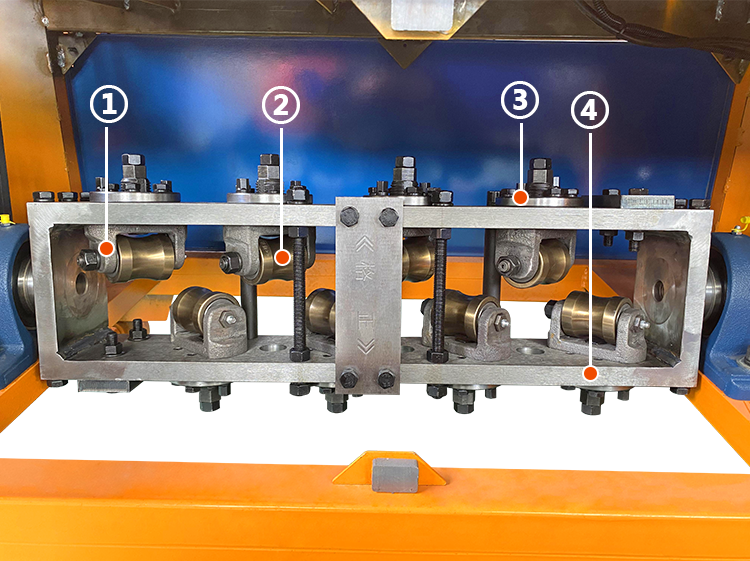

Product Structure Component Diagram

ST-12 hydraulic steel bar bending machine

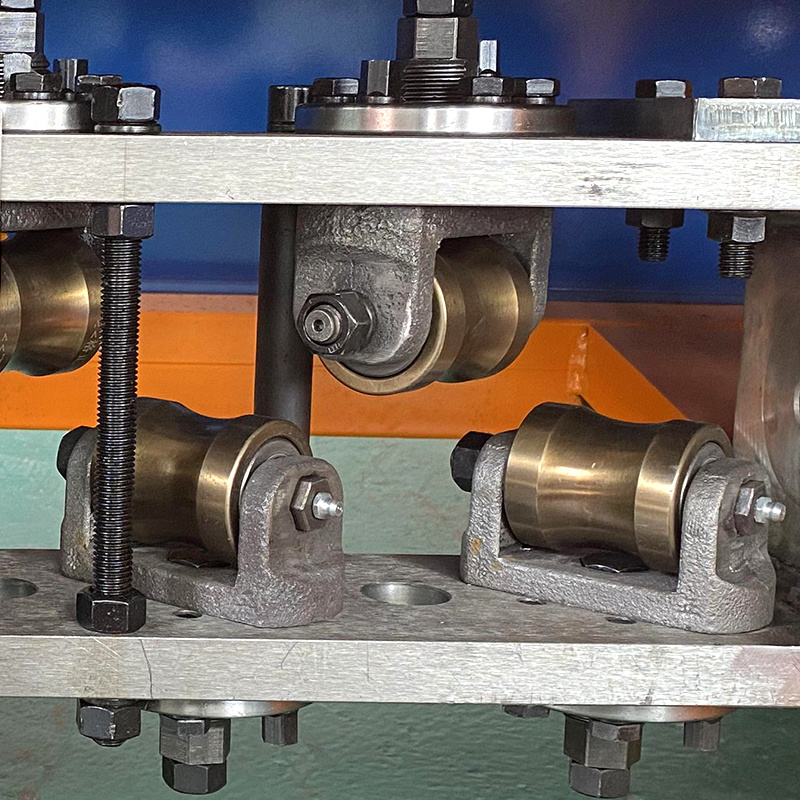

1. Rack

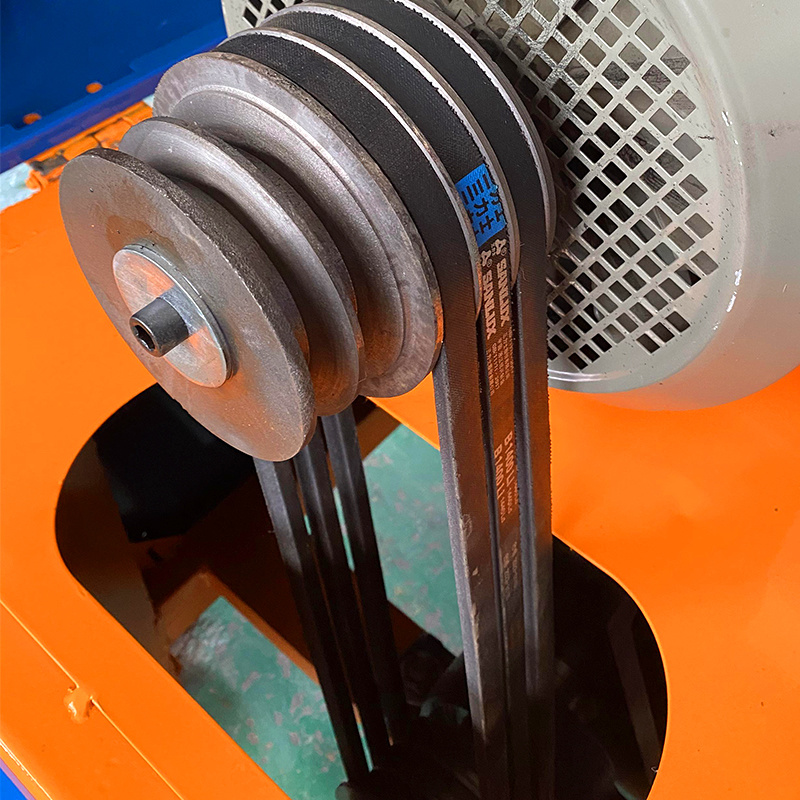

2. Motor

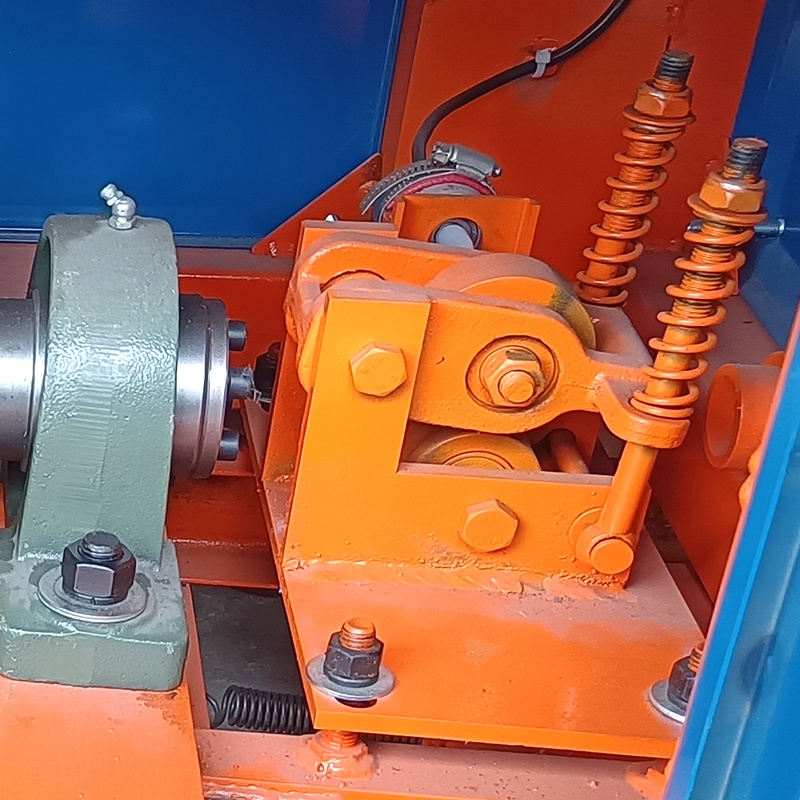

3. Oil pump

4. Straightening box

5. Meter counting wheel

6. Electric box

7. Solenoid valve

8. Oil storage tank

9. Special reinforced sheared oil cylinder

CANBONG MACHINERY

WIDE RANGE OF ADAPTATION

Meet various engineering needs

Real estate

exploitation project

Bridge

High Way

Rebar processing

and distributing centel

Our products are widely used in all kinds of real estate exploitation projects, highway and railway, bridge and tunnel, rail transit, underground pipe gallery, nuclear power station and hydro power station and other kinds of infrastructure construction. As well as prefabricated buildings, steel processing and distribution centers and other fields.

CANBONG MACHINERY

STRAIGHTENING REBAR EASILY

Before straightening

After straightening

6 REASONS FOR BUYING

Pursue quality and performance with heart

National standard

pure copper motor

Whole machine

hickening

Famous

CNC panel

Thousand ton

meter wheel

Thickening and

straightening frame

Upgrade high

pressure cylinder

High power pure copper motor

It can works for 48 hours continuouslyHigh power and energy efficiency but low noise with long service life

4kW

Power

1 year

warranty

Pure copper

coil

High efficiency

High-power

Low energy

consumption

The entire machine adopts

Thickened materialHigher quality and longerlife

High quality brand CNC panel

Can be set according to the work requirements.

Simple and convenient operation mode by one-click operation

Specially made thickened

shear 60 oil cylinder

Smaller displacement directly reduces motor power loss

and power displacement makes straightening and cutting off power stronger

The four core components

of the straightening frame are upgradeHeavy eight wheel straightening frame and the thickened hollow adjusting wire to protect the flange straightening wheel adjustment more quickly. Each straightening wheel is equipped with 2 brand bearings, straightening rebar more smoothly.

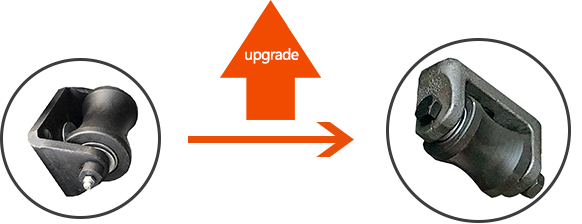

1. Upgraded bearing holder

Ordinary bearing holder

Short life

It is made of ordinary steel plate by stamping process

Low strengthen that makes it deformed easilyVS

Cast steel bearing holder

The life is three times

that of a ordinary bearing holder

With high strength2. Upgraded straightening wheel

Straightening wheel made of bearing steel

About 400 tons of rebar can be adjusted

VS

Straightening wheel made of chromium 12 platinum-vanadium

More than 1500 tons of rebar can be adjusted

And the original 2 bearings are upgraded to 43. Upgraded ring flange

Ordinary straightening

frame

Fragile and not easy to replace

If it is damaged, it have to replace the whole straightening frameA ring flange is added to ensure that

1000 ton of rebar can be processedTwice the lifespan

Three layer screw protection

Damage only requires replacing the flange plateA ring flange is added to ensure that

2000 ton of rebar can be processedChromium 12 high strength splint

With 6-ply screws for protection

The overall life increased by 4 time4. Upgraded frame

The whole straightening frame has been thickened

sturdy and durable

CANBONG MACHINERY

REAL TIME DISPLAY

CANBONG MACHINERY

PROFILE OF COMPANY

Company plant

Group photo of employees

Office

High precision advanced production line

Canbong Machinery Co., LTD., founded in 2006, is located in Heshan city, the famous hometown of overseas Chinese in The Guangdong-Hong Kong-Macao Greater Bay Area, China. We are a steel bars processing machinery who comprehensive enterprise focusing on the research and development, design, production and sales of various high-end and provide the overall solution.

Our products are widely used in all kinds of real estate exploitation projects, highway and railway, bridge and tunnel, rail transit, underground pipe gallery, nuclear power station and hydro power station and other kinds of infrastructure construction. As well as prefabricated buildings, steel processing and distribution centers and other fields. At present, our company have developed more than 200 distribution points in China, and our products are sold to more than 30 countries and regions around the world. We have already reached cooperative relations with more than 50 well-known construction units at home and abroad. Widely praised by our customers and formed a "integrity, quality" brand reputation of Canbong gradually .

Our company adhere to the road of independent innovation and have a number of practical patents and appearance patents in the field of steel bars processing. We adhere to quality-oriented, customer-centered, and constantly pursue breakthroughs and committed to providing more reliable machinery and equipment for the construction industry and more intimate customer service.

According to the market demand, our company continue to invest in research and innovation, have a number of practical and appearance patents. In recent years, by taking advantage of the development of the Guangdong-Hong Kong-Macao Greater Bay Area. We have responded to the cooperation between China and Europe, strengthened learning and exchanges with China and Germany to introduce our technology actively. So that improve our level of research, development and production.

At the same time, we will cooperate with Guangzhou Branch of National Supercomputer Center to set up a R&D center, strengthen the exchange and cooperation with domestic talents and experts in the field of mechanical automation and speed up to break through the key technologies, so that Canbong products can always maintain the edge in the marketplace.

CANBONG MACHINERY

THE WHOLE PROCESS INTIMATE SERVICE

Escort the whole process from plan to completion

1·Provide free project consulting

2·Free customized solutions

3·Mechanical equipment and the use of technology to deliver

4·After-sale tracking service, until the project completion

From project negotiation, customized solution according to demand, to machine and equipment delivery, to unified after-sales service, until the completion of the project, we will follow up for your project escort, to provide you with not only machinery, but also the whole process of intimate service.

CANBONG MACHINERY

LOGISTICS AND PACKAGING

Our company launch lifelong intimate service. Provide experience, technology also tracking support, escorts and eliminate the worries of our customers.

Directly sale from the factory and adequate supply of goods. And we have a variety of logistics options, fast and safe.

Get in touch with us