WQL32E-2T-V01 Bending Center

零售价

市场价

Product number:WQL32E-2T-V01

重量

kg

库存

隐藏域元素占位

- Product Description

-

Model WQL32E-2T-V01 Bending Speed(rpm/s) 0~9 Moving Speed(m/s) 0.5~1 Power Source 380V 50Hz Total Power(kW) 19.5 Average power consumption(kW/h) 5 Maximum Bending Angle

(°)Up Side Bending 0-180 Down Side Bending 0-110 Angular Precision(°) ±2 Minimum Midsection Size(mm) Φ10 560 Φ32 580 Maximum Curved Edge Size(m) 10 (Customizable) Length Accuracy(mm) ±3 Minimum length of curved edge(mm) 90 Minimum bending bar length(mm) 500 (unilateral) Strength level of machinable steel bar <Φ32mm≤IV Compound Bending(mm) 10~32 Unidirectional Bending (Up Side Bending)(mm) 00 Diameter φ(mm) 10 12 14 16 18 20 22 25 28 32 Bending Amount 6 5 4 3 2 2 2 1 1 1 Boundary Size(Customizable)

(mm)~12000×2580×1525 Dedicated to infrastructure projects such as roads and bridges

Canbong Vertical CNC Bending Center

BIDIRECTIONAL BENDING CNC BENDING CENTER

1. High performance PLC control system, HD touch screen, workers can quickly learn and operate, and the operation is more simple, processing rebar more safe, stable and reliable.

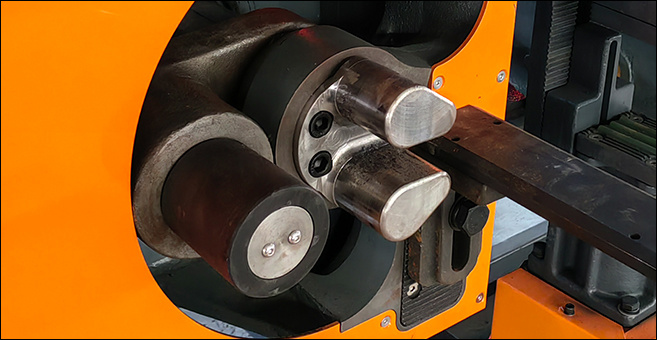

2. The curved bushing is made of special steel and processed by heat treatment process to make it wear-resistant and durable. The walking mechanism uses high precision gear and rack to drive, the machine walking distance is accurate, and the noise is low.

3. Multiple rebar processing can be formed at the same time with high production efficiency.

Service Guarantee

DIRECTLY SALES

FROM FACTORY

LIFE LONG

SERVICE

SOLUTION

WITHIN I HOUR

7*24 HOURS OF

TECHNICA

EXPERIENCE

SUPPORT FOR

ANYWHERE

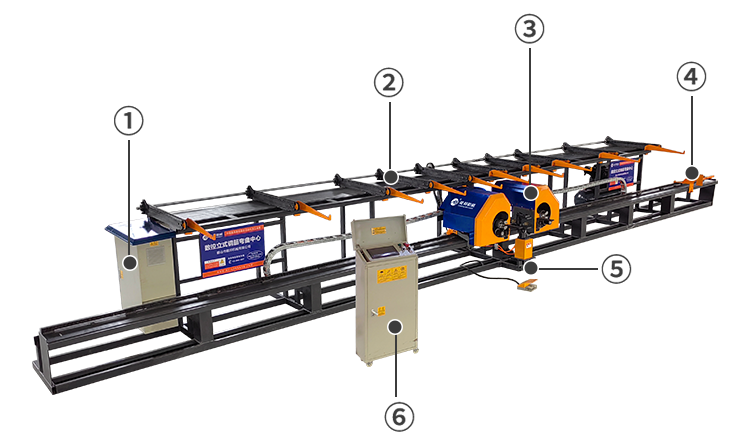

Product Structure Component Diagram

WQL32E-2T-V01 Bending Center series

1. Control cabinet

2. Material rack

3. Bending host

4. Align Structure

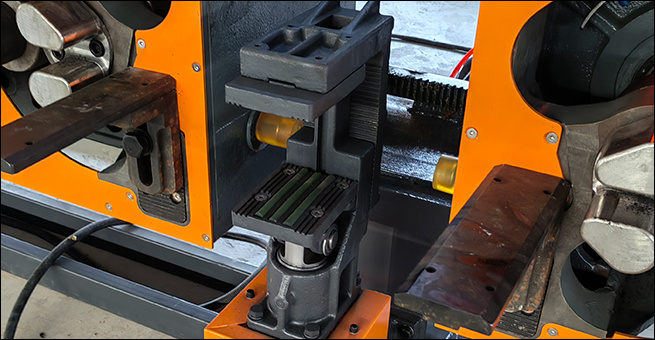

5. Pressing mechanism

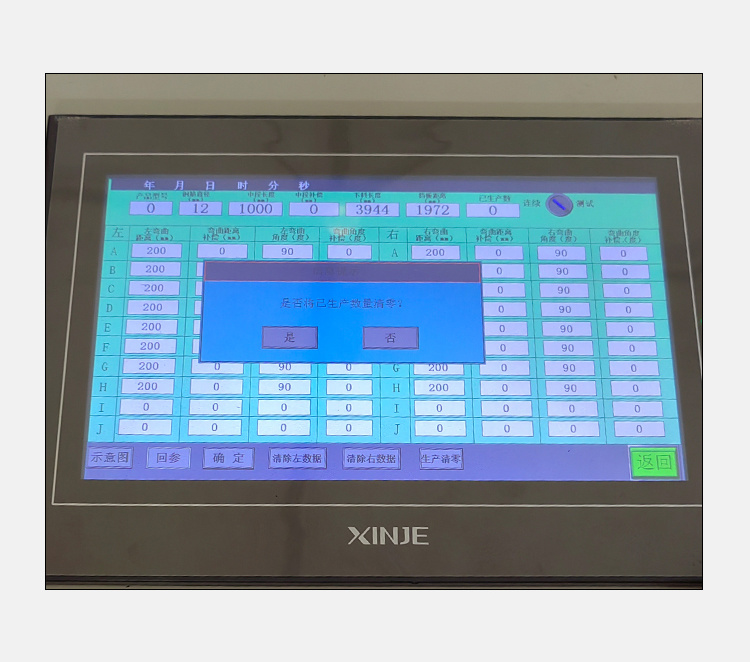

6. Operation screen

CANBONG MACHINERY

WIDE RANGE OF ADAPTATION

Meet various engineering needs

Railway

construction

Bridge

construction

Urban

tunnel construction

Construction of nuclear power and hydropower stations

Our products are widely used in all kinds of real estate exploitation projects, highway and railway, bridge and tunnel, rail transit, underground pipe gallery, nuclear power station and hydropower station and other kinds of infrastructure construction. As well as prefabricated buildings, steel processing and distribution centers and other fields.

6 REASONS FOR BUYING

Pursue quality and performance with heart

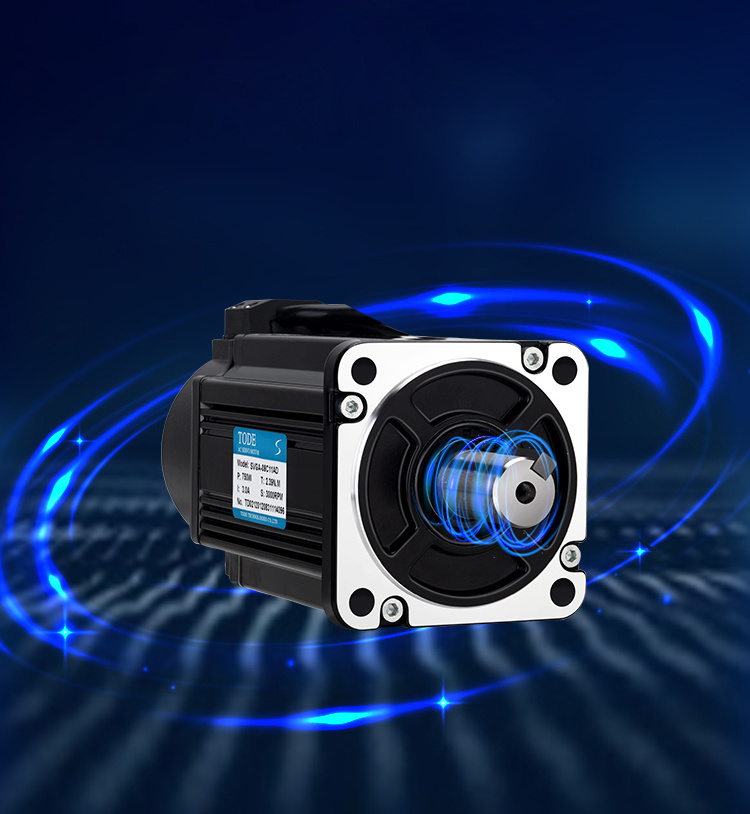

High precision

servo motor

Automatic

feeding

Biaxial

bending

High quality

bearings

Accurate walking and bending angles

PCL control

touch screen operation

High precision servo motor with strong power

Small size and high progress servo with high-precision and long service life

International large factory, magnetic steel production, strong overload capacity

Military standard connection plug

Original Japanese encoder

Adopting anti bending technology with over 5 million cycles

High precision, durable and durable

Motor protection level IP65

Advanced heat dissipation design process with lower temperature rise

6 CORE TECHNOLOGIES

Ultra strong performance and advanced technology easily

adapt to various industrial automation applications

Multi-mode control

Speed position

Torque modePulse signal

24V and 5V

Two waysAnti-interference

Built-in filter jammer

Strong anti-interference ability

Communication

RS232、RS485

ENTHERCAT communicationConstant torque output

Output force distance

Keep constantFeedback signal

23bit high-precision encoder

More precise positioning

Automatic feeding

The support frame bears two tons of weightBrand reduction motor drive

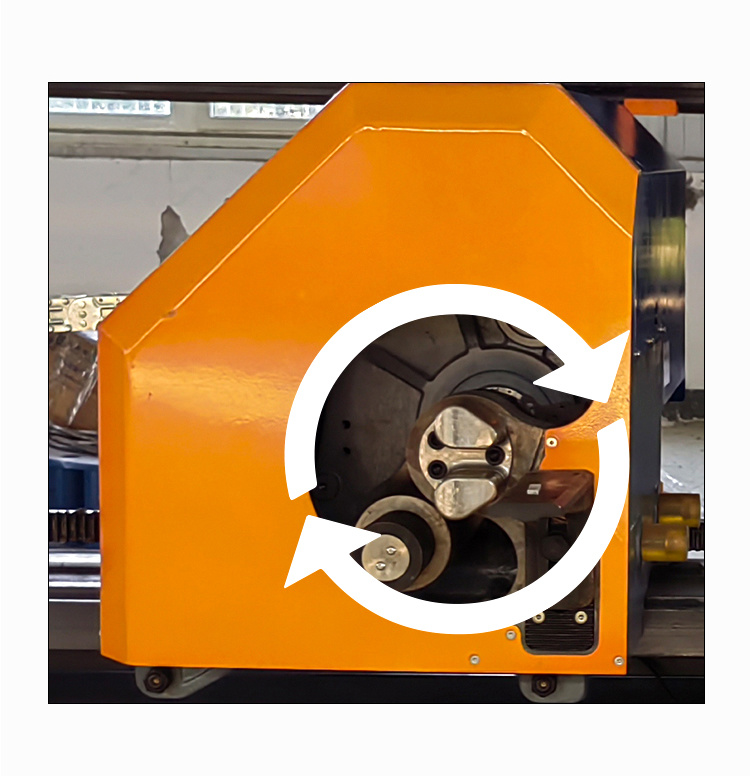

Bidirectional bending

Strong processing abilityBend up 0-180 ° and down 0-110 °

Strict selection of brand high-quality bearings

Durable and durableLess virtual space, durable and non cracking

Accurate walking and bending angles

High precision walking and bending system

Intelligent operation

simple and easy to use

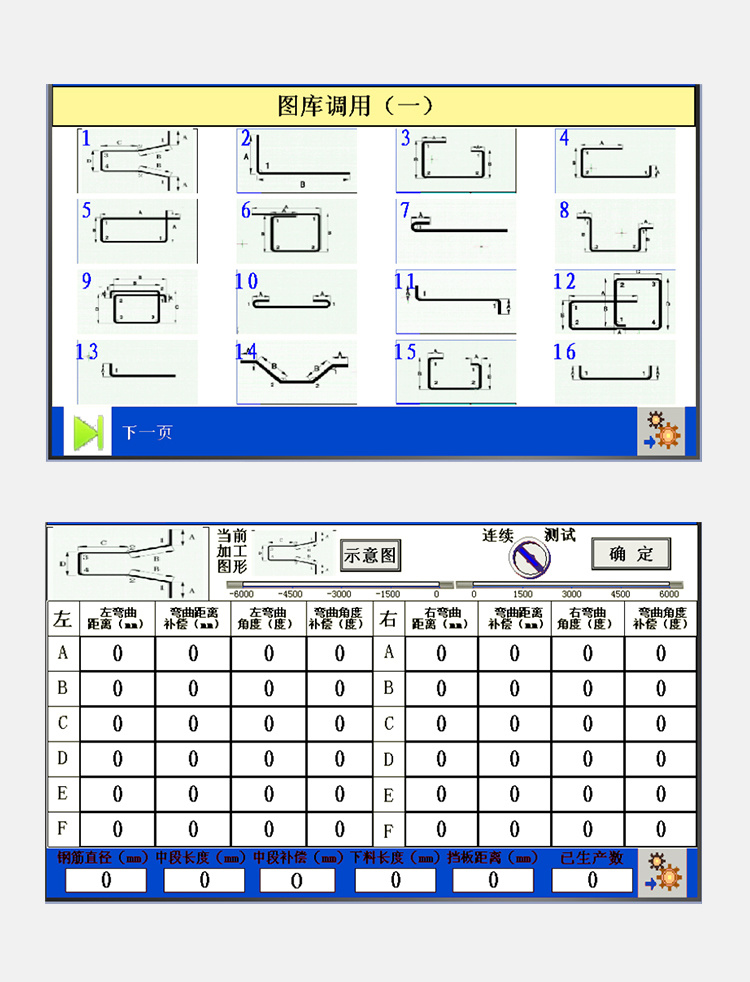

PCL controlled CNC touch screen

Rich preset graphics library

Customization is also convenientMultiple selection and customizable bending styles

Sufficient materials

and solid workmanship

Thickening the body and strengthening the workbench

Precision steel solid accessories are durable and durable

The frame is made of solid materials, stable and durable

The fixture and cylinder are thick and use sufficient materials

The material rack has sufficient material and strong load-bearing capacity

CANBONG MACHINERY

REAL TIME DISPLAY

CANBONG MACHINERY

PROFILE OF COMPANY

Company plant

Group photo of employees

Office

High precision advanced production line

Canbong Machinery Co., LTD., founded in 2006, is located in Heshan city, the famous hometown of overseas Chinese in The Guangdong-Hong Kong-Macao Greater Bay Area, China. We are a steel bars processing machinery who comprehensive enterprise focusing on the research and development, design, production and sales of various high-end and provide the overall solution.

Our products are widely used in all kinds of real estate exploitation projects, highway and railway, bridge and tunnel, rail transit, underground pipe gallery, nuclear power station and hydro power station and other kinds of infrastructure construction. As well as prefabricated buildings, steel processing and distribution centers and other fields. At present, our company have developed more than 200 distribution points in China, and our products are sold to more than 30 countries and regions around the world. We have already reached cooperative relations with more than 50 well-known construction units at home and abroad. Widely praised by our customers and formed a "integrity, quality" brand reputation of Canbong gradually .

Our company adhere to the road of independent innovation and have a number of practical patents and appearance patents in the field of steel bars processing. We adhere to quality-oriented, customer-centered, and constantly pursue breakthroughs and committed to providing more reliable machinery and equipment for the construction industry and more intimate customer service.

According to the market demand, our company continue to invest in research and innovation, have a number of practical and appearance patents. In recent years, by taking advantage of the development of the Guangdong-Hong Kong-Macao Greater Bay Area. We have responded to the cooperation between China and Europe, strengthened learning and exchanges with China and Germany to introduce our technology actively. So that improve our level of research, development and production.

At the same time, we will cooperate with Guangzhou Branch of National Supercomputer Center to set up a R&D center, strengthen the exchange and cooperation with domestic talents and experts in the field of mechanical automation and speed up to break through the key technologies, so that Canbong products can always maintain the edge in the marketplace.

CANBONG MACHINERY

THE WHOLE PROCESS INTIMATE SERVICE

Escort the whole process from plan to completion

1·Provide free project consulting

2·Free customized solutions

3·Mechanical equipment and the use of technology to deliver

4·After-sale tracking service, until the project completion

From project negotiation, customized solution according to demand, to machine and equipment delivery, to unified after-sales service, until the completion of the project, we will follow up for your project escort, to provide you with not only machinery, but also the whole process of intimate service.

CANBONG MACHINERY

LOGISTICS AND PACKAGING

Our company launch lifelong intimate service. Provide experience, technology also tracking support, escorts and eliminate the worries of our customers.

Directly sale from the factory and adequate supply of goods. And we have a variety of logistics options, fast and safe.

Get in touch with us