No data

Centralized processing and distribution of steel bars

Jul 07,2023

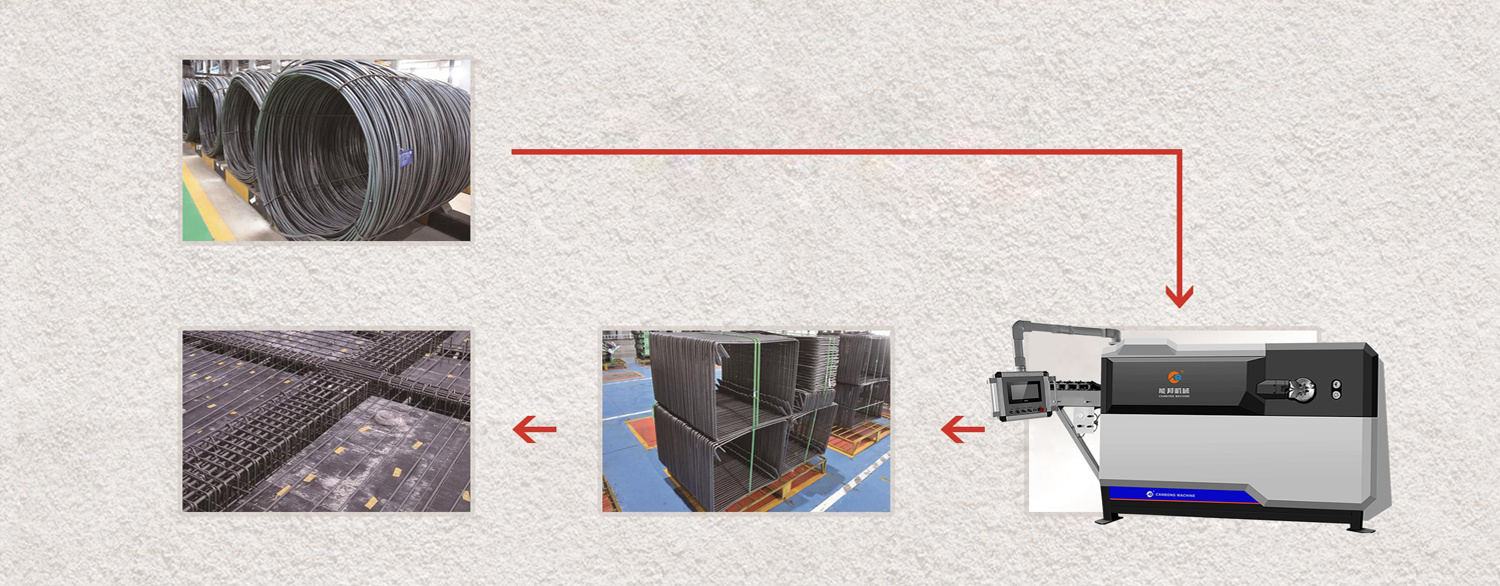

· Centralized processing and distribution of steel bars

As one of the important parts of China's construction industry, the construction of roads and bridges accounts for a large proportion in the demand for steel bars. At present, China's traditional steel bar processing is mainly carried out at the construction site, relying on manpower to process and produce. This processing method has the disadvantages of low degree of mechanization, low production efficiency, high labor intensity, difficult to control processing quality and time schedule, high waste of materials and energy, high processing cost, many potential safety hazards, large land occupation, and large noise, which restricts the improvement of project quality to a certain extent. The centralized processing and distribution of commercial steel bars is an inevitable trend of market development, which will trigger the second revolution of China's construction logistics. For domestic steel logistics and building construction, it is a new service model

1. Initiate the demand

Processing and production

2. On-demand distribution of steel bars centralized processing and distribution

refers to the centralized processing of steel bars used for construction through mechanization and mature processing technology in a special factory or production and processing base, construction steel bars through the centralized processing of the factory system, through the digital production management operating system induction and sorting, the centralized processing of steel bars for classification storage and transportation, used in the construction of steel bars can be more systematic transportation management. Ensure the quality and timeliness of steel bars delivered to various construction sites, and complete the entire centralized processing and distribution of steel bars through logistics and distribution.

|

standard |

Traditional on-site processing |

Centralized processing and distribution |

|

Quality accuracy |

Manual processing, weak controllability |

Automated production, high precision |

|

Material loss |

Waste is serious and material loss is large |

Mass production, low material loss |

|

deposit |

Occupy a large area of the construction site for storage |

No storage issues |

|

Shipping method |

On-site processing |

Logistics delivery |

|

Duration impact |

Long lead time |

Short lead times |

Automatic processing process of wire bar straightening and bending hoop

Automatic processing process for bar bar shearing and bending

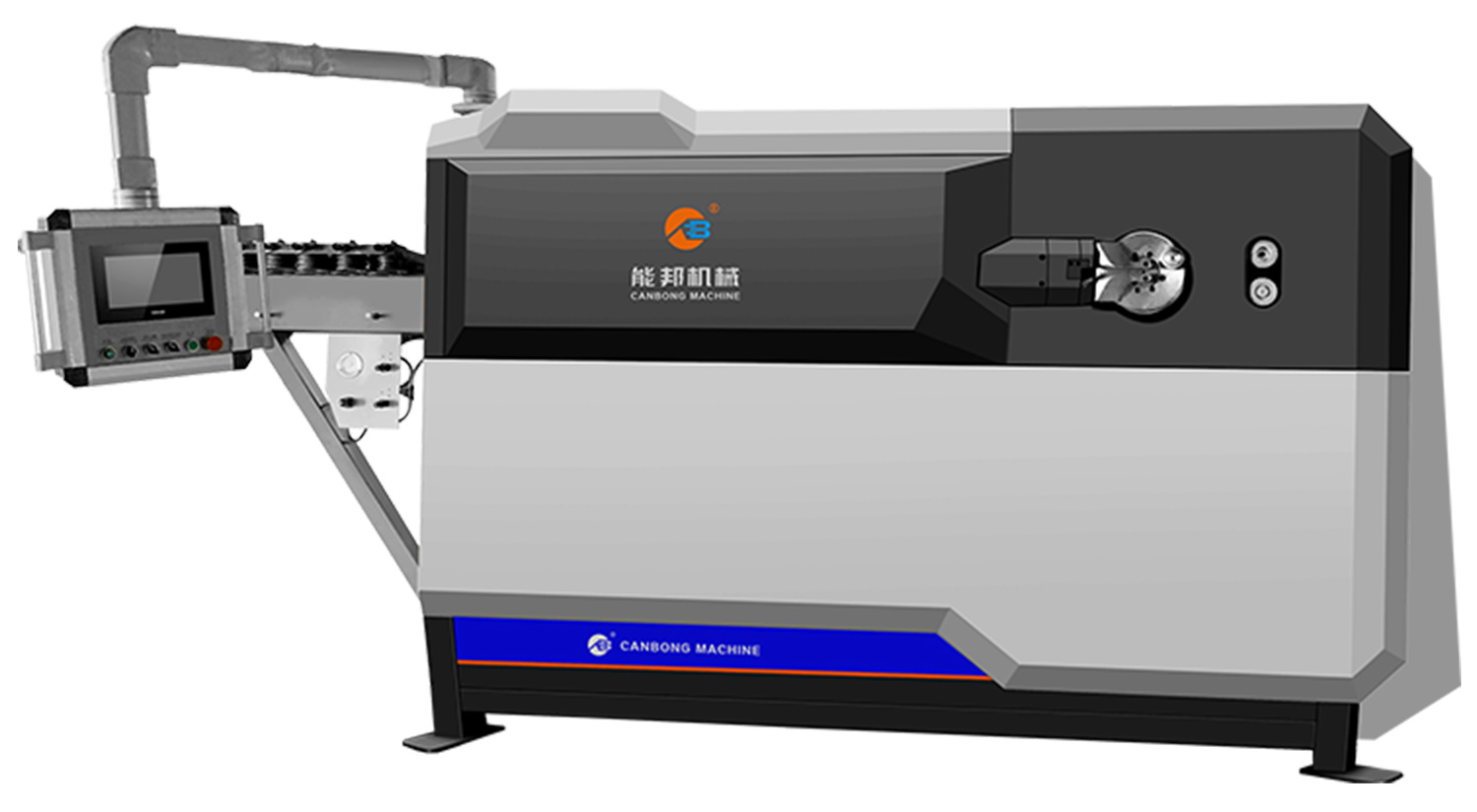

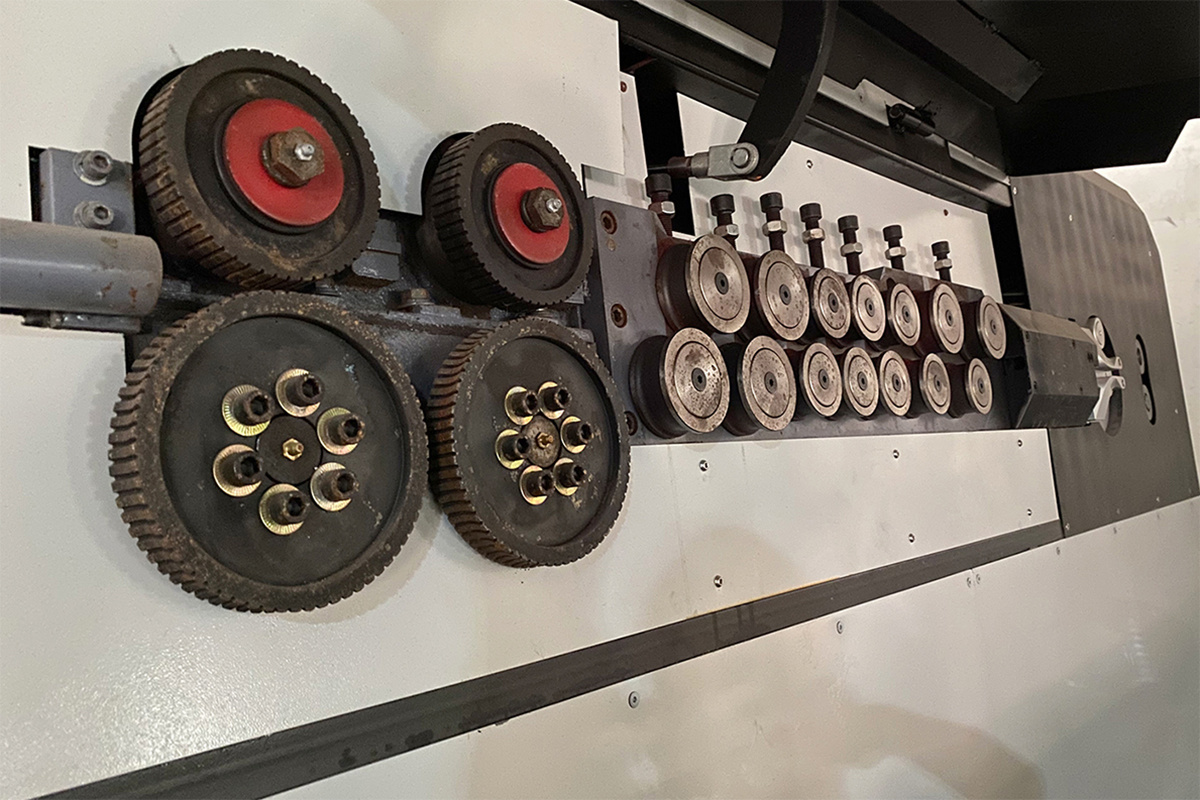

· CNC rebar hoop bending machine

CB-WG12D-2

CB-WG12D-2 CNC rebar bending machine adopts pneumatic and efficient double-station multi-function bending mechanism, the production speed is increased by 20%, and the bending of various special shapes can be completed efficiently, and the bending arc angle is R6-R35 (center pin diameter 12-70). Large bevel design, large processing range, can process all kinds of stirrups within 1670mm, can also process small stirrups as small as 70X70 (mm).

Single rebar processing diameter: medium 5mm-medium 13mm

Double rebar processing diameter: medium 5mm-medium 10mm

Maximum bending angle: 180

Bending direction: bidirectional

Maximum traction speed: 110m/min

Maximum bending speed: 1200°/sec

Total power: 27kw

· Multi-function CNC rebar bending machine

CB-WG12F-1

CB-WG12F-1 multifunctional CNC rebar bending machine can process all kinds of stirrups and plate bars. Disc type two-stage telescopic bending mechanism, high return bending efficiency, telescopic splice mechanism, avoid steel bar channeling; Large-scale structure design, the width of the processing plate rib hook can reach 1 meter, and the maximum plate bar length can reach 12m; The maximum stirrup side length reaches 2100mm; Four-wheel servo drive return mechanism design to achieve multi-step return bending.

single steel bar processing diameter: medium 5mm-medium 13mm

Double steel bar processing diameter: medium 5mm - medium 10mm

Maximum bending angle: 180

Bending direction: bidirectional

Maximum traction speed: 110m/min

Maximum bending speed: 1200°/sec

Total power: 31kw

Host size: 16000x1950x2740mm

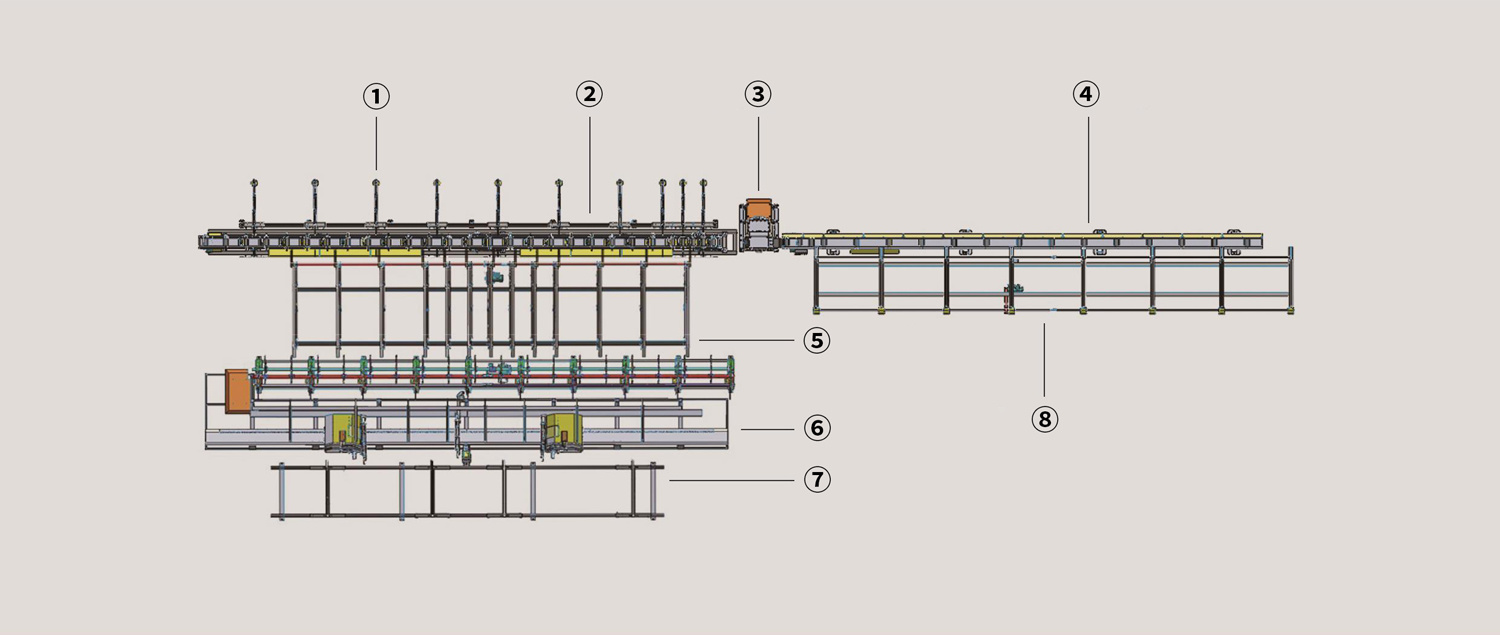

· Shear bending linkage production line

CB-XQ120+WQL32E-2T-V01

CB-XQ120+WQL32E-2T-V01 shear bending linkage production line is a bar processing line composed of shearing line and vertical bending center through linkage device, which can complete the fixed-length shearing of bar bars with a diameter of 10-38mm. The vertical bending center can realize two-way automatic bending of steel bars, adopt pneumatic clamping method, and install telescopic clamping mechanism to meet the processing of steel bars in small and middle sections.

Shear diameter: medium 10mm-medium 38mm

Shear length: 750-12000mm

Bending diameter: medium 10mm-medium 32mm upper

Bending angle: 0-180°

Minimum middle length: 300mm

Shear width: 200mm

Conveying speed: 50m/min

Bending speed: 0-9r.p.m

Bending angle: 0-120Total

Power: 27kg

(1) Cut the finished product storage rack.

(2) Rear conveying return track

(3) Shearing host

(4) Front conveying track

(5) Shearing finished product conveying

(6) Bending integrated machine

(7) Piece storage rack

(8) Storage platform

· CNC rebar hydraulic shearing production line

CB-GJW150B

CB-GJW150B CNC rebar hydraulic shearing production line can realize the cut-to-length demand for 800-12000mm bar rebar. The fixed-length mechanism is equipped with fixed-length baffles of different lengths, which are adjusted by the servo control system to accurately control the shear length. The anti-runout automatic pressing device of the shearing mechanism will not cause steel bar sliding phenomenon, and the production line cooperates with the plane mesh forming machine to realize the orbital transmission of shearing finished products and semi-finished products.

Single rebar processing diameter: medium 5mm-medium 13mm

Double rebar processing diameter: medium 5mm-medium 10mm

Maximum bending angle: 180

Bending direction: bidirectional

Maximum traction speed: 110m/min

Maximum bending speed: 1200°/sec

Total power: 27kw

· CNC beveled rebar bending center

CB-G2W50

CB-G2W50 CNC inclined rebar bending center feeding support can lift the original steel bar, which is convenient for automatic feeding and blanking, which can significantly improve work efficiency. The bending mechanism and traveling mechanism are all driven by servo motor, and can be bent forward and reverse. The bending mold adopts a modular design, which can replace the bending shaft according to the needs of processing different diameter steel bars, and the replacement process is convenient and fast.

Diameter of processed rebar: medium 10mm - medium 50mm

Bending speed: 54°/sec

Bending machine moving speed: 0.5-1m/s

Upper bending angle: 0-180

Lower bending angle: 0-120

Minimum midsection length: 1100mm

Total power: 27kW

Dimensions: 12500x2200x1020mm

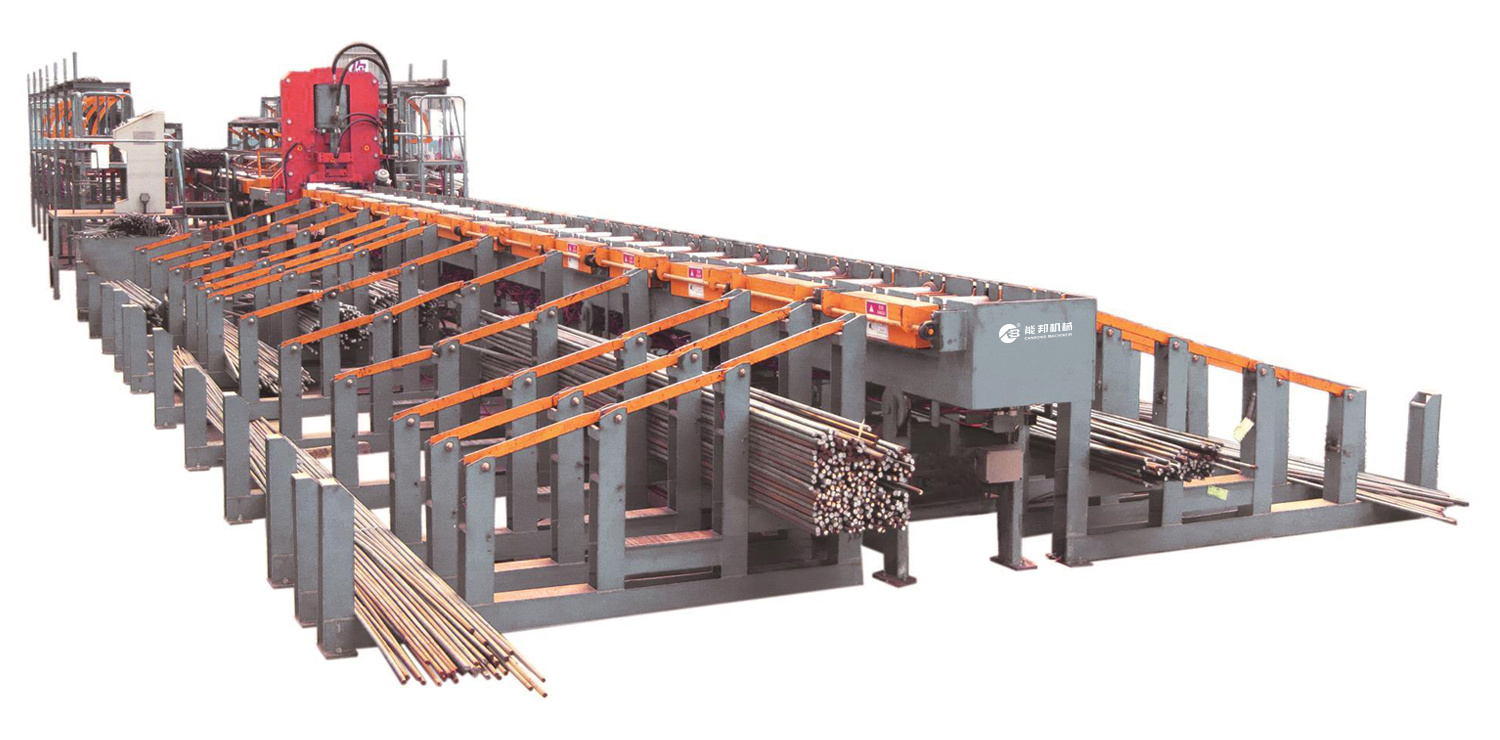

· CNC rebar sawing sleeve wire production line

CB-JQTS400-2TM

CB-JQTS400-2TM CNC rebar sawing and nesting production line adopts the design concept of streaming, with multi-stage raw materials and finished product storage mechanism, raw materials are transported to the sawing host through the storage platform and complete high-speed sawing, after the sawing is completed, the steel bar is transported to the sleeve guide platform, and the two ends of the steel bar are polished through the conveying roller table. The main mechanisms of the equipment include: rebar storage station, front conveying device, rebar sawing host, rear conveying device, rebar storage part, automatic wire nesting, and operation console control part.

Sawing diameter: medium 16mm - medium 50mm

Cutting width: 400mm

Conveying speed: 90m/min

Sleeve diameter: medium 16mm - medium 32mm

Sleeve length: 80mm

Sawing length: 1200-12000mm

Total power: 46kW

Dimensions: 32000X6400X2400mm

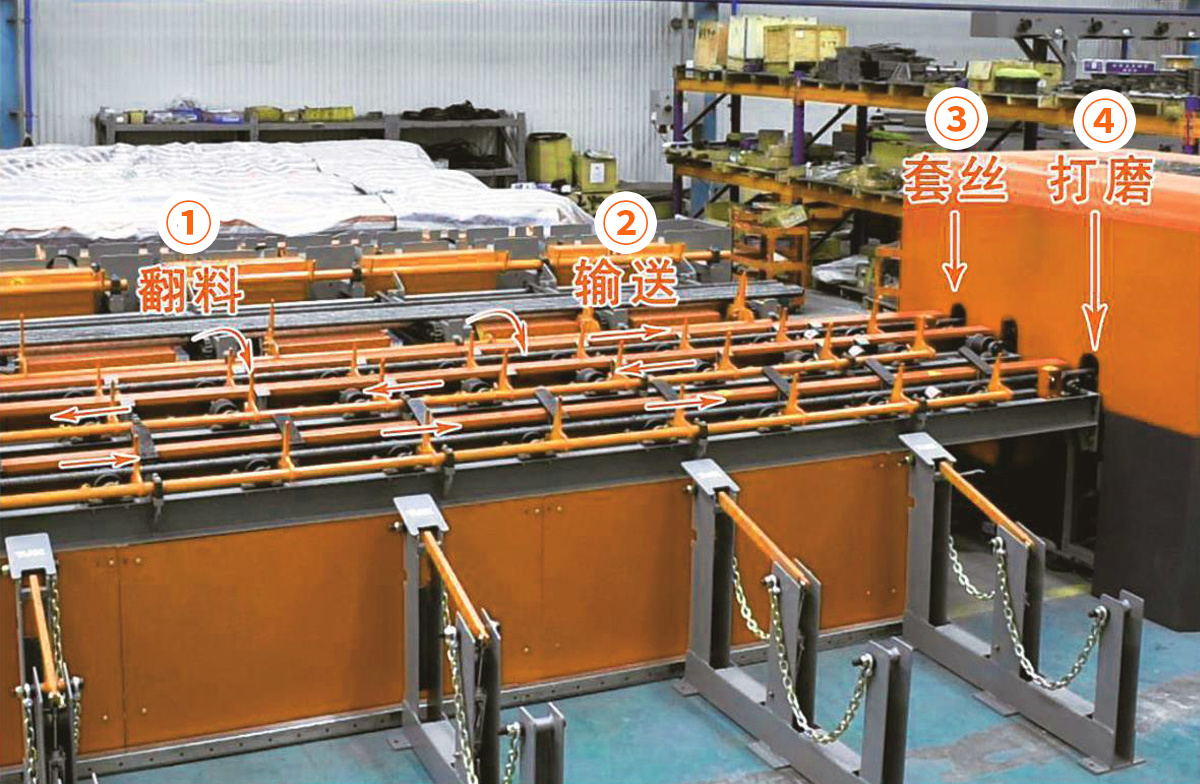

(1) Turning

(2) Conveying

(3) Nesting

(4) Grinding

· CNC rebar indiscriminate ruler straightening sorting machine

CB-GS50

CB-GS50 CNC rebar straightening and sorting machine can divide the rebar tailing, starting from the vibration mechanism to vibrate, discharge, convey, straighten, and sort all of the whole bundle of rebar in this production line continuously. The straightening mechanism is equipped with a length counter, which can separate the random ruler steel bars, and can store the steel bars of similar length in the same lattice silo; The design of the steel bar straightening mechanism is added, which can straighten the bent steel bar and improve production efficiency.

Sorting bar diameter: medium 12mm - medium 50mm

Sorting rebar length: 3000-13000mm

Alignment speed: 60m/min

Conveying speed: 230m/min

Straightening speed: 80m/min

Total power: 50kW

Dimensions: 29600x5200x1630mm

· Five-axis CNC rebar automatic bending center

CB-G5L25A

CB-G5L25A five-axis CNC steel bar automatic bending center is composed of five groups of bending heads, supporting 5 sets of standard molds, making large diameter double pull hook and stirrup bar efficiency; Using PLC operating system combined with touch screen control interface, the steel bar graphic can be directly called, and the operation is simple and convenient; Frequency conversion motor control, high efficiency; Each graphic has a separate calibration function to ensure accurate angles and reduce rebar waste.

Sorting bar diameter: medium 12mm - medium 50mm

Sorting rebar length: 3000-13000mm

Alignment speed: 60m/min

Conveying speed: 230m/min

Straightening speed: 80m/min

Total power: 50kW

Dimensions: 29600x5200x1630mm

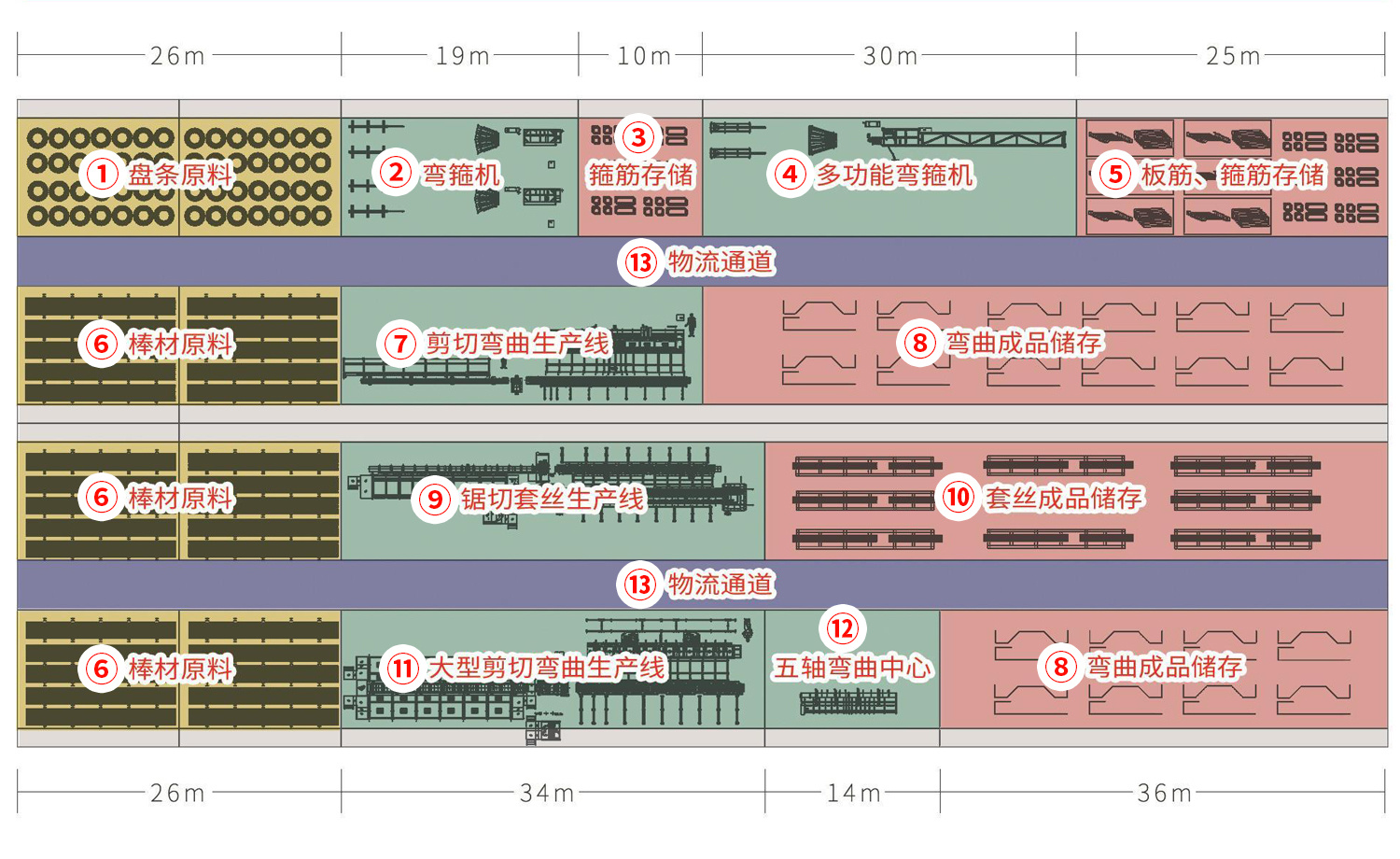

· Layout planning rebar processing workshop

(1) Raw materials of wire rods

(2) Hoop bending machine

(3) Stirrup storage

(4) Multi-function hoop bending machine

(5) Storage of plate ribs and stirrups

(6) Bar raw materials

(7) Shear bending production line

(8) Bend finished product storage

(9) Sawing nesting production line

(10) Finished wire nesting product storage

(11) Large shear bending production line

(12) Five-axis bending center

(13) Logistics channel

The steel bar centralized processing center is 110 meters long and 52 meters wide, and adopts a 4m wide driving lane, which divides the factory area into raw material storage area, production and processing area, and semi-finished product storage area. The configuration of CNC rebar bending machine, bar rebar shearing and bending production line, CNC rebar sawing and nesting production line and other domestic advanced automatic CNC equipment can greatly improve production efficiency, effectively control the quality of finished products, reduce the number of labor in the production line, reduce the difficulty of on-site management and safety risks.

|

serial number |

Device name |

Device model |

Staffing |

Capacity |

|

1 |

CNC rebar hoop bending machine |

CB-WG12D-2 |

1 person |

8T/day |

|

2 |

Multifunctional CNC rebar bending machine |

CB-WG12F-1 |

1 person |

12T/day |

|

3 |

CNC rebar shearing production line |

CB-XQ120 |

1 person |

40T/day |

|

4 |

CNC hydraulic rebar shearing production line |

CB-GJW150B |

2 person |

100T/day |

|

5 |

CNC vertical rebar bending center |

WQL32E-2T-V01 |

2 person |

30T/day |

|

6 |

CNC beveled rebar bending center |

CB-G2W50 |

2 person |

50T/day |

|

7 |

Five-axis CNC rebar automatic bending center |

CB-G5L25A |

2 person |

40T/day |

|

8 |

CNC rebar sawing sleeve wire production line |

CB-JQTS400-2TM |

2 person |

800 sticks/day |

CNC steel processing equipment capacity and staffing table

Previous

Next

Previous

Next

Related Products

Related Cases